|

|

Copyright

©

A.D. 2008–09

by M. D. Van

Norman.

|

|

The Argentine m1927 is an example of the

widespread popularity of the Colt-Browning design.

|

I suspect

that there are two primary reasons for

this enduring popularity. First, the .45-ACP cartridge is perceived to

be a

potent handgun round, which appeals to shooters who obsess over the

“stopping power”

of their firearms. Second, the short, single-action trigger makes

accuracy with

the pistol fairly easy to achieve.1

Add in the long service life of the U.S. m1911

series and the irrepressibility of American pride, and you have a

recipe for

success.

While my assessment of the Colt-Browning platform may be more

objective, I can still appreciate the innovation represented by the

basic design, constrained as it was by what were essentially

19th-century military specifications. The idea of building my own

version was also very appealing. Well-worn U.S. m1911s can easily fetch

$1,000 or more, so when the opportunity to purchase a comparatively

inexpensive Argentine m1927, Sistema Colt, pistol presented

itself, I jumped at the chance.

The Argentine model of A.D. 1927 was a licensed

copy of the Colt system (U.S. m1911A1), though the first 10,000 units

were manufactured in Connecticut. These pistols were produced until A.D. 1966 and were almost completely identical to

their U.S. military counterparts.2

My m1927 was made in Argentina in A.D. 1951 and

exhibited plenty of scratches and cosmetic wear, but mechanically it

appeared to be in excellent shape.

|

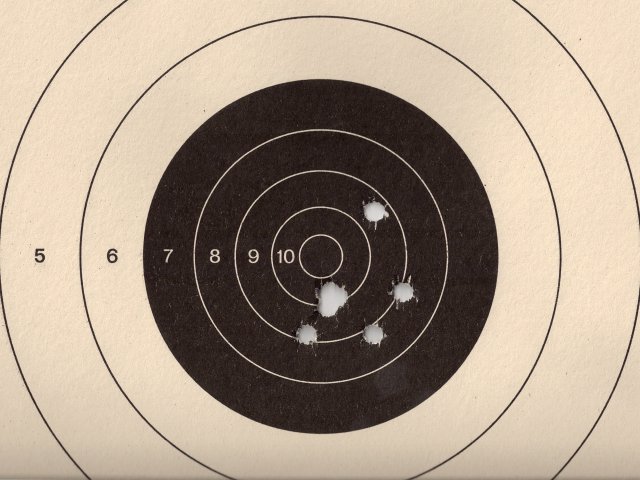

At about seven yards, I was still able to

place shots within a three-inch circle with my unmodified m1927 pistol.

|

Once I found the time, I

headed to the local shooting range to give my m1927 a quick function

check with a variety of ammunition, including round-nose, flat-point,

and hollow-point bullets. I went through four magazines without any

real trouble. I had one failure to feed with the hollow points, but

that appeared to be a problem with an unidentified magazine.

Accuracy was fair, given that I was out of practice and

that the pistol suffered from a heavy trigger and poor military sights.

I was

able to group my shots within a three-inch circle at defensive ranges.

The shots were consistently high but centered horizontally, which was

very encouraging. Compared to the baseline performance of my .45-ACP

SIG-Sauer P220, however, the m1927 still needed a lot of work.

|

Despite a

lot of mostly cosmetic wear on the outside, my m1927’s internal parts

were in very good condition.

|

My next step was to

completely disassemble the pistol for a detailed inspection and a

thorough cleaning. I used a few simple tools for the job, though it is

said that the Colt-Browning pistol can be used as its own toolbox. Once

I had it apart, I was pleased and a little bit surprised to discover

that the gun’s internal parts were in perfectly serviceable condition.

There was some honest wear, but nothing was close to being worn out.

I decided to rebuild my m1927 into my vision of a combat pistol, which

meant it

would need to be easy to hold, aim, and fire. The grip profile would

have to be reduced, the sights would need to be improved, and the pull

weight of the trigger would have to be lightened. As it happened, I

tackled

the heavy trigger pull first.

|

Replacing the sear spring brought the

trigger pull down to an acceptable weight.

|

While mercifully short,

the m1927’s trigger still required a

substantial amount of force to release the hammer. This didn’t hurt

leisurely, close-in

accuracy at the shooting range too badly, but it certainly made the

pistol more difficult and less comfortable to fire. I wanted to bring

the pull weight down to about four pounds, light enough to shoot very

easily but still heavy enough to require intentional effort.

A professional trigger job can cost hundreds of dollars and mostly

involves

the gunsmith carefully filing and polishing the hammer, sear,

and

disconnecter. However, my research indicated that there are two springs

that also affect the pull weight in the Colt-Browning system. The

mainspring propels the hammer

forward when the trigger is pulled, so some of its tension must be

overcome during the firing process. The sear spring engages the sear,

disconnecter, and grip safety, so it too resists the trigger

pull. Since the mainspring is also part of the recoil system, I decided

to leave it alone. I bought a light sear spring made by Cylinder & Slide,

accomplishing my

trigger job for about five bucks.3

|

With some effort, I installed a flat

mainspring housing to reduce the size of the m1927’s grip.

|

At the same time, I

started to minimize the grip profile by replacing

the arched mainspring housing with a flat one. I purchased a drop-in

housing made by Wilson Combat

and quickly realized that I would still have to

fit it to my pistol by hand to prevent it from binding the grip safety.4 My

existing hobby files

weren’t well suited for the task, but I was able to get the job done

after a few hours of diligent work.

To complete this process, I bought a pair of slim grip panels from the Cocobolo Supply Company. Their

installation wasn’t any easier. The original grip-screw bushings were

staked in, so I had to remove them carefully to avoid damaging the

frame. Using a special driver bit from Brownells and applying slow but

steady force, I was able to get the old bushings out successfully.

Once the new bushings were in place and secured with Loctite Threadlocker,

installing the slimmer stocks was

easy enough. Half-checkered, “ranger”-style panels retained the

functionality of

checkering without giving the pistol the appearance of either a

military sidearm or a presentation gun. Combined with the flat

mainspring housing, they reduced the grip profile by a quarter of an

inch in circumference.

|

Compare the

slimmed-down m1927 on the left to the unmodified pistol on the right.

|

The next improvement was significantly more expensive. A

combat handgun should be able to be

aimed quickly and effectively even in low-light conditions, so tritium

night sights were a required upgrade. I lacked the experience and

the

equipment needed to properly install sights on a Colt-Browning pistol,

so in addition to buying the sights, I would need a professional

gunsmith to install them.

After weighing my options, I decided to purchase a new Caspian Arms slide cut for the

popular Novak sight system.

This allowed me to preserve the original slide and to benefit from more

modern metallurgy. However, the Caspian

design necessitated a new

firing pin and firing-pin stop, so I went ahead and replaced the

extractor as well. I also added an extra-power firing-pin spring from Wilson Combat to provide a

small

measure of safety should the pistol ever be dropped.5

Assembling the new slide required quite a bit of file work on the

firing-pin stop and just a touch on the extractor. Everything seemed to

fit together correctly, but I eventually made another trip to the range

to verify this. Using new magazines, I went through the same variety of

ammunition as before without any trouble whatsoever.

|

The new Caspian slide required some

additional fitting to match my pistol’s frame more closely.

|

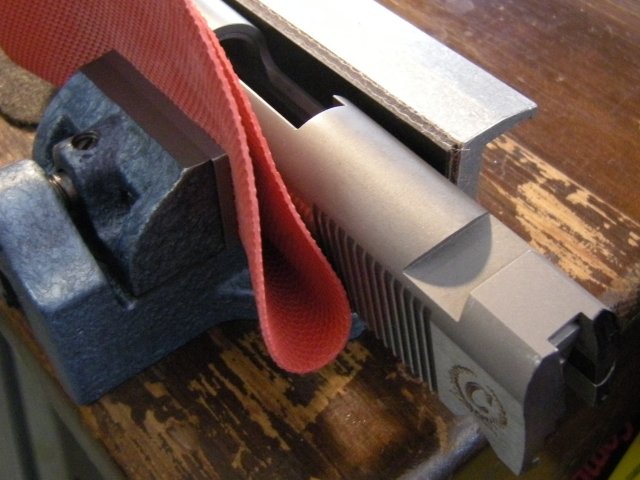

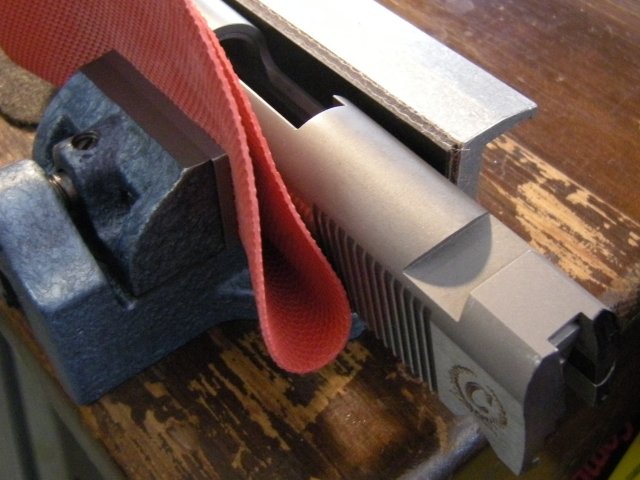

However, the Caspian

slide was not a perfect match to my

m1927 frame. There was a slight overhang at the rear, so I decided to

shorten the slide for a better fit. This meant I needed to buy more

tools, but eventually I marked the slide, loaded it into a table vise,

and went to work with a mill file.

I worked very slowly in order to maintain the original contours. After

each pass of my file, I re-inked the back of the slide as a reference.

In this manner, I eventually cut my way down to the desired depth. I

finished the process with a couple passes from a hobby file and the

judicious application of fine sandpaper.

|

My m1927 saw very little change in

performance after the initial modifications.

|

Meanwhile,

I re-installed the original slide and made another trip to the range to

see how well my previous improvements performed. The results were

really no better than my first outing but were still acceptable.

However, after seven magazines, my right hand came away bloodied by

repeated blows from the long hammer spur … which made me reconsider my

$5.00 trigger job.

|

The Caspian slide had an acceptable finish

after two applications of cold bluing solution.

|

With the rear of the slide and the frame blended to my

satisfaction, I prepared the slide for finishing. I used fine sandpaper

to smoothen the steel, to soften the sharp edges, and to remove a few

small scratches. I followed this with my trusty pot scrubber,

burnishing the surface to a pleasant sheen.

I then blued the slide in a two-step process. First, I heated the slide

in the oven and quickly applied a coat of Brownells Oxpho-Blue with cotton

patches. I let this cure overnight, but after I cleaned and burnished

the steel again the next day, I noticed that the dark-gray finish had

some prominent streaks.

For the second coat, I switched to Birchwood Casey Super Blue.

This left the slide a deeper black, but the streaks were still visible

upon close inspection. Since I wasn’t trying to win a beauty contest

with this pistol, I decided that this was good enough, packed up the

slide, and shipped it off to Novak

Design for sights.

|

I installed the Caspian slide, now

equipped with Novak low-mount night sights.

|

Two weeks

and $200 later, my slide returned with tritium sights in place. I chose

the bar-dot configuration on the theory that the different markings

would enable quicker acquisition and alignment of the sights under

stress. The installation job itself appeared professional and secure.

I was ready for another trip to the range, but the thought of that long

hammer spur biting my hand continued to bother me.

|

I further upgraded my FM-Caspian m1927

with a Cylinder & Slide trigger-pull kit and a King’s grip safety.

|

So I

installed a Cylinder &

Slide trigger-pull kit that I had previously blued. Rated at four

pounds, the kit gave the pistol a crisp, relatively light trigger pull.

I paired the new hammer with a King’s

Gun

Works grip safety, though I had to tweak the sear spring to

keep the safety from flopping about.

|

At 25 feet, I shot a 2.25-inch group with my FM-Caspian.

Note the four-round “cloverleaf” in the 10 ring.

|

Once the

weather cooled down, I took advantage of a furlough day and headed to

the shooting range. While I wasn’t expecting any major improvements in

accuracy, I did manage a 2.25-inch group with premium Winchester

hollow-point cartridges. After the hollow points, I tried

flat-point and round-nose ammunition in a variety of new magazines.

I experienced only two minor problems. The slide twice failed to return

to battery with Ed Brown

magazines and also failed to lock back on Chip McCormick magazines. The

former problem will probably resolve itself after

a

couple

hundred

more

rounds, as the new

components wear into the the gun. The latter is probably indicative of

a worn slide stop, which I will eventually have to repair or replace.

But my hands came away unscathed.

|

|

I

swapped the original slide stop for a heavy-duty replacement from

Evolution Gun Works.

|

After some

experimentation, I decided to change out the slide stop. Evolution Gun Works provided a

heavy-duty replacement, which seemed to resolve the lock-back problem.

Another trip to the range validated this conclusion, and I was able to

run through 10 different magazines from four different manufacturers

without a single malfunction.

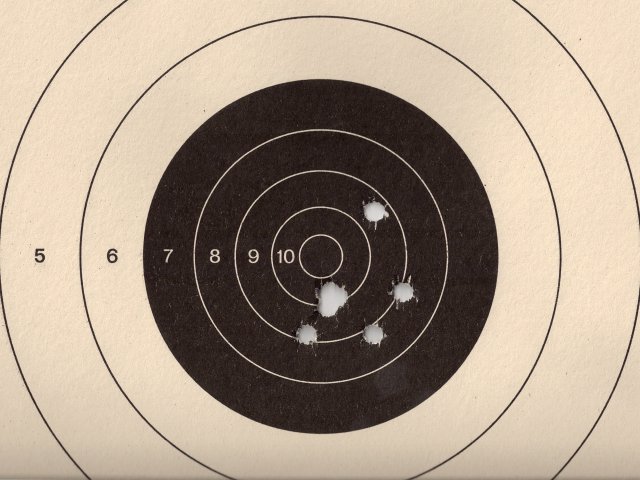

I was also pleasantly surprised when I turned in a tight group with my

first magazine. Other than making the pistol easier to shoot, I haven’t

done anything to intentionally improve its accuracy, but this group

showed that the gun can do its part when I do mine. However, my shots

have been drifting to the right and are no longer consistently

centered. This is probably due to incorrect finger placement on my

part, but I can’t rule out a mechanical cause without further testing

at the range.

|

This eight-round, 1.06-inch group

demonstrated the potential accuracy of my FM-Caspian pistol.

|

After more than two years

and 500 extra dollars, this project is effectively done. Without making

any permanent modifications, I transformed a well-worn relic into a

modern combat pistol,6

ready once again to defend life and liberty.

During this process, I gained a new appreciation for the Colt-Browning

platform embodied by the U.S. m1911 series, by the Argentine m1927, and

by the host of commercial variants still being manufactured today.

In fact, the enduring popularity of the 1911-style pistol turned out to

be its best feature. The wide variety of replacement parts available on

today’s market gave me the opportunity to build the pistol that I

wanted. Even the lament from Col. J. D. Cooper that I quoted at the

bottom of this page no longer applies.

|

1

|

The

first time I fired a 1911-style pistol, I was quickly shooting the

centers out of my targets at seven yards, albeit with a well-tuned

Smith & Wesson Performance Center model.

|

2

|

Besides

their different markings, there are supposedly only two external,

cosmetic differences between the U.S. m1911A1 and the Argentine m1927

pistols.

|

3

|

The light sear spring worked very well on this pistol, but I

have had less spectacular success on other examples. To achieve a

similar result with an earlier

m1927, I had to install a drop-in trigger-pull kit from Cylinder & Slide, which

was significantly more expensive.

|

4

|

Pressing

the grip safety disengages the disconnecter, allowing the trigger to

act on the sear, which holds the hammer in the cocked position. |

5

|

The

basic Colt-Browning design lacks a firing-pin block, so an unmodified

pistol can potentially discharge if dropped. The danger is remote, but

simple precautions should be taken to mitigate this risk. |

6

|

Such

a weapon doesn’t exist, except in the narrowest of contexts.

Conventional wisdom holds that no one would choose to fight with a

handgun, but civilian shooters also won’t find themselves with

select-fire carbines and on-call reinforcements.

|

|

|